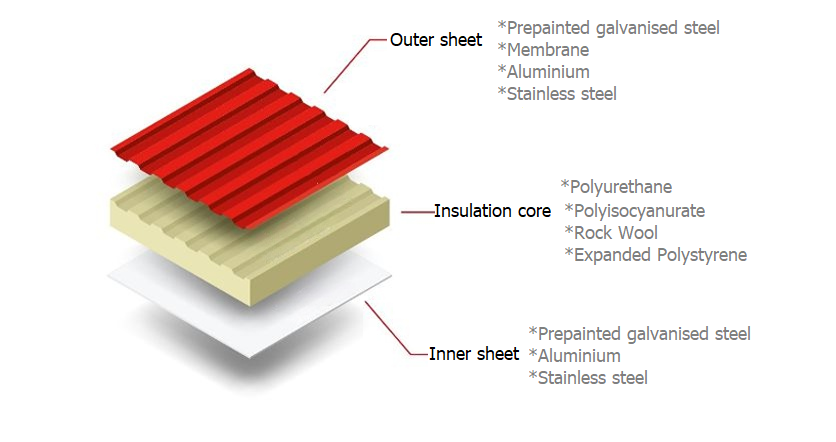

Sandwich Panel is a form of insulating building material that consist of insulating core which is placed between two metals. The insulating core is made from different materials such as rigid polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), and rockwool.

Some types of sandwich panels are waterproof, soundproof, and fireproof. It is durable and environmentally friendly. It does not produce or harbour bacteria. It is the ideal building material that can be applied in all constructions such as steel, wooden or concrete constructions. The sandwich panels are used as curtain materials. In other words, the panels are fastened to either the steel framework or any other carrier that acts as the structural force of a building.

Advantages and Disadvantages of Sandwich Panels

Advantages of sandwich panels include:

The main disadvantage of sandwich panels is their inability to withstand additional structural loads.

Uses of Sandwich Panel:

Sandwich Panels are used in several types of residential, commercial and industrial buildings. This include but not limited to; prefabricated houses, Cold storage facilities, factories and production facilities, agriculture buildings, laboratories, Hypermarkets, Groceries, supermarkets, military buildings, warehouses, sports, arenas, recreational facilities, silos, logistics hubs, social structures.